Sharpening Rods

IOXIO® Rods

Ein IOXIO® Ceramic sharpening rod is the perfect knife sharpener for sharpening and keeping your kitchen knives sharp

Choose the right sharpening rod: the grit counts! The higher the grit, the finer the grind. With IOXIO® you have the choice: our sharpening rods are color-coded to make your selection easier.

IOXIO® sharpening rods

Choosing the right rod

Which grain size for which knife

Japanese knives, damask steel knives, carbon steel knives, fine grinding

IOXIO® Sharpening Rod Ultrafine

Grit size: F1300/J4200

very fine

Japanese knives, Damascus steel knives, Carbon steel knives, Fine grinding, Knife lovers

IOXIO® Sharpening Rod Origin

Grain size: None - pure Al2O3

Professional use

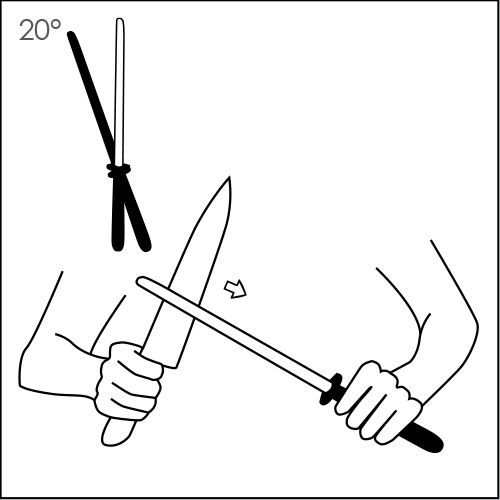

IOXIO® Sharp Guide, the simple solution for learning or improving the perfect sharpening with a rod.

Always sharpen in the right angle

Sharpening aid for sharpening rods

Guides the knife over the sharpening rod at a constant angle

Protects against scratches caused by incorrect use

Perfect addition for inexperienced and non-expert chefs

The IOXIO® Sharp Guide is available in the following angles:

Sharp Guide 30° with a cutting angle of 30°(sharpening angle 15°)

Sharp Guide 35° with a cutting angle of 35°(sharpening angle 17.5°)

Sharp Guide 40° with a cutting angle of 40°(sharpening angle 20°)

Original Ceramic - Made in European Union

Quality, durability, resource-saving

from the manufacturer

At IOXIO®, development, manufacture and production all come from a single source and from the heart of Europe. Regional production enables us to provide more personalised support at all stages of production.

All raw materials used in the manufacture of IOXIO® products are REACH-approved, certified and sourced exclusively from EU-based distributors.

Made in the EU also means shorter transportation routes and climate-friendly shipping.

IOXIO® Ceramic rod

Why ceramic rods?

Sharpening steel or rod, the difference

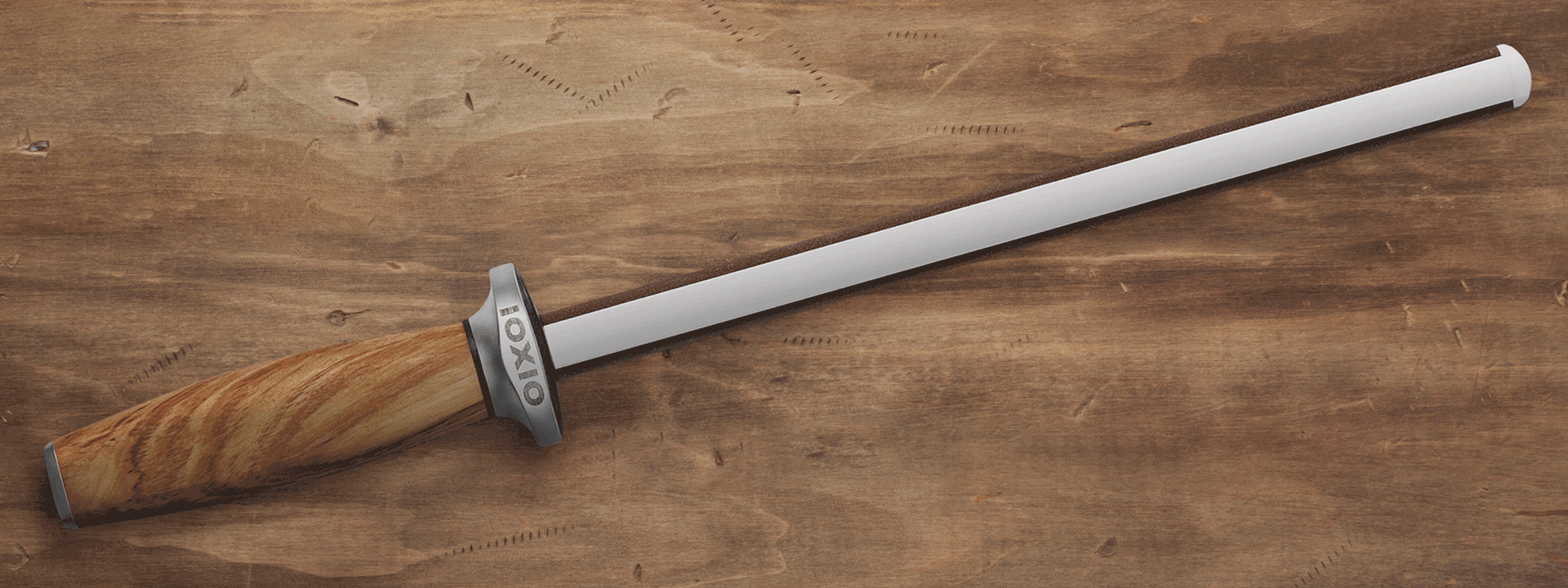

IOXIO® sharpening rods are made of sintered ceramic and combine the hardness of the grinding stone with the shape of the conventional sharpening steel. IOXIO® sharpening rods are made of solid material and have an abrasive surface that is not coated. In contrast to coated sharpening rods, ceramic hardly wears at all, as the abrasive grain is added to the raw material and compacted at high temperature. As ceramic is harder than steel, the ceramic rod hardly wears at all during sharpening.

This makes our all-ceramic sharpening steels more durable than grinding rods.

Quality, durability and sustainability - IOXIO® ceramic rod.

Extra tip: The larger the knife, the longer the sharpening steel. Use an extra-long sharpening steel with a working length of at least 26 cm for large chef's knives.

FAQ - Ceramic sharpening rod

It depends on your knife. The sharpening angle for chef's and kitchen knives is between 10 and 20 degrees. For modern kitchen knives we recommend a sharpening angle of 15 degrees.

The color indicates the grain size of the sharpening rod and is used for visual differentiation. It is a visual distinguishing feature to quickly find the right rod and serves the better undercutting

- Blue Ceramic has F360/J800) is for sharpening dull knives

- White Ceramic (F1000/J3000) is for resharpening and keeping sharp

- The Duo sharpening rod is a combination of blue and white ceramic (patent holder is Udo Rieser)

- Light blue ceramic with grainsize F1300/4200 are for sharpening extremely hard knives

- Cream white is even finer than F1300/4200 and perfect for daily use in professional kitchens. Cooks choose this sharpening rod.

IOXIO ceramic sharpening rods are not coated, but consist of solid material. The grain is added to the raw mass and then compacted at high temperature, which is why wear of the rod is almost impossible.

Our sharpening rods are durable and qualitative products.

Sharpening rods are originally made of steel. A sharpening rod can be made of any material. The important thing is that a sharpening rod as well as the grain is harder than the knife to be sharpened.

Remember:A sharpening steel is for keeping sharp. A ceramic sharpening rod is for sharpening.

To achieve a sharp result, it is important that you use your ceramic sharpening rod correctly.

-

To do this, place the end of the blade at the tip of the IOXIO ceramic sharpening rod. Make sure that the angle between the knife blade and the IOXIO ceramic sharpening rod should always be approx. 10 to 20 degrees. This value depends on the initial sharpening of your knife.

To do this, place the end of the blade at the tip of the IOXIO ceramic sharpening rod. Make sure that the angle between the knife blade and the IOXIO ceramic sharpening rod should always be approx. 10 to 20 degrees. This value depends on the initial sharpening of your knife. - Pull the knife in a slight arc on the IOXIO ceramic sharpening rod down.

- Starting from the end of the blade to the beginning of the knife blade.

The speed of your movement does not matter here, the angle of 10 to 20 degrees is important. Please take your time when sharpening and consciously pull the blade over the sharpening rod. - Repeat this movement behind the ceramic to sharpen the other side of the knife blade.

- Repeat Steps 2 and 3 a few times, alternating sharpening the front and back sides of the knife blade.

- Afterwards, clean the blade with a soft damp cloth to remove steel residue caused by honing on the rod.

Advantage of oval sharpening rods: With the wider grinding surface succeeds a more uniform grinding pattern on the blade. For regular honing, we recommend blue ceramic. The white rod is ideal for fine honing. The use is safe even for inexperienced cooks due to a metal protection toggle.